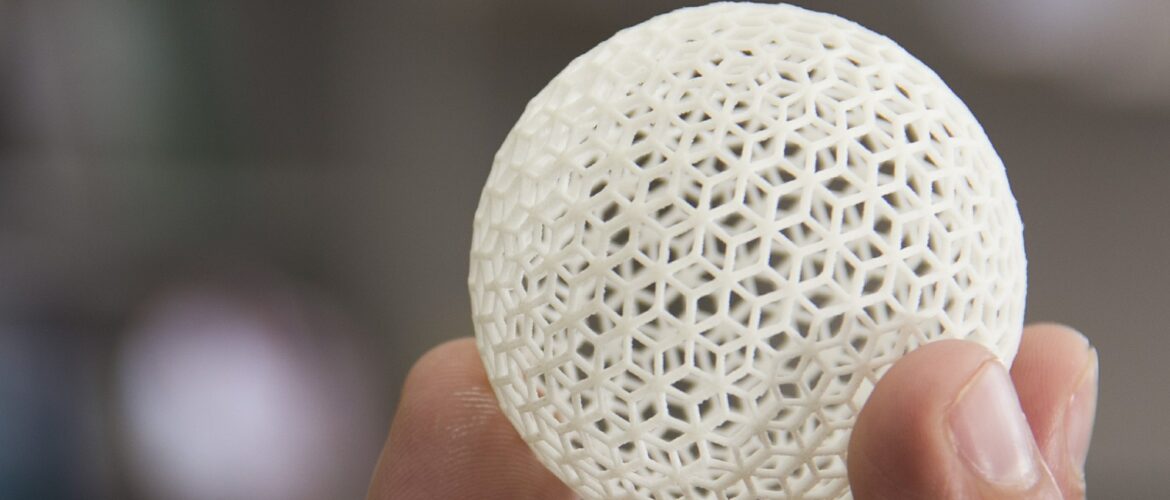

Bioprocesses currently used in industry are primarily based on batch and fed-batch mode, where yields and productivities have peaked and require technological innovations to uplift this cap on productivities. Traditional cell immobilization technologies (e.g. Ca alginate- or polysaccharide-based gels), a potential strategy to ensure cell retention, have limited success due to fragility of the encapsulating material. In recent years, advances in additive manufacturing provide opportunities to move beyond traditional immobilization paradigm by three-dimensional (3D) printing of novel materials with biological catalysis capabilities that can empower a new industrial revolution.

The 3D printing of living materials allows immobilization of biological catalysts and has numerous advantages, e.g.:

(i) printing of co-cultures without the risk of strains out-competing each other;

(ii) significantly extended cell retention and material stability;

(iii) possibility to functionalize the material;

(iv) decoupling of biomass production from product formation, which increases substrate-to-product yield.

Related publications:

- , H., , O.,, K. S.,, A., , A. Jõul, P., P. M.,, G. de La C. , B.,, N., V. Lahtvee, P- J., Kumar. R. (2025). Acidification by nitrogen metabolism triggers extracellular biopolymer production in an oleaginous yeast. DOI: https://doi.org/10.1101/2025.05.04.652101

- Johnston TG, Fillman JP, Priks H, Butelmann T, Tamm T, Kumar R, Lahtvee PJ, Nelsson A (2020). Cell‐Laden Hydrogels for Multikingdom 3D Printing. Macromolecular Bioscience, 2000121, DOI: 10.1002/mabi.202000121

- Priks H, Butelmann T, Illarionov A, Johnston TG, Fellin C, Tamm T, Nelsson A, Kumar R, Lahtvee PJ (2020). Physical confinement impacts cellular phenotype within living materials. ACS Applied Bio Materials, DOI: 10.1021/acsabm.0c00335