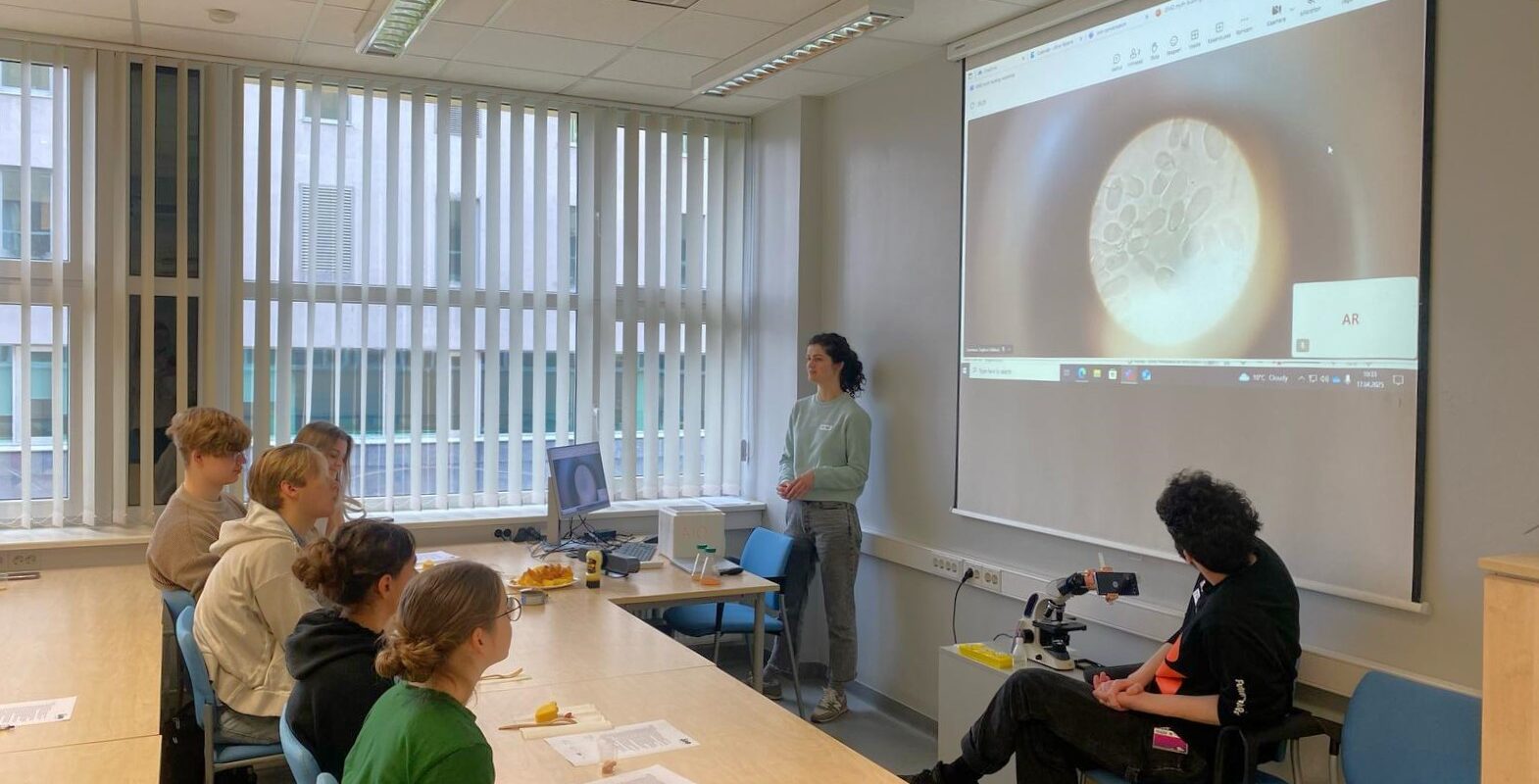

Alīna Reķēna took part in Yeast Genetics and Genomics course, from July 22 to August 12 at Cold Spring Harbor, New York, USA

The legendary yeast course at CSHL, with more than 50 years of history, offered lectures on the fundamentals of yeast genetics, daily seminars from leaders in the yeast community, and 10 laboratory experiments that showcase the methods needed in a modern-day yeast lab.

Lecture topics included yeast cell cycle, tetrad analysis, genetic interactions, genome sequencing, imaging and functional genomics.

The yeast community has pioneered many of molecular and genetic techniques we rely on today. The goal of experimental section was to provide with sufficient hands-on experience apply these techniques in our own laboratories – from classical and modern genetic approaches (mutant isolation and characterisation, tetrad analysis, complementation), to molecular genetics (yeast transformation, gene replacement, gene fusion and mutation), as well as use of the yeast deletion set, multiplex deep sequencing, cytological approaches (epitope tagging), and yeast cell imaging.

Many thanks to fellow course participants for exciting discussions and fun learning, to the seminar speakers for their insights and inspiration, and to the course instructors, teaching assistants and coordinators for their dedication and wisdom.

Photo credits: Constance Brukin